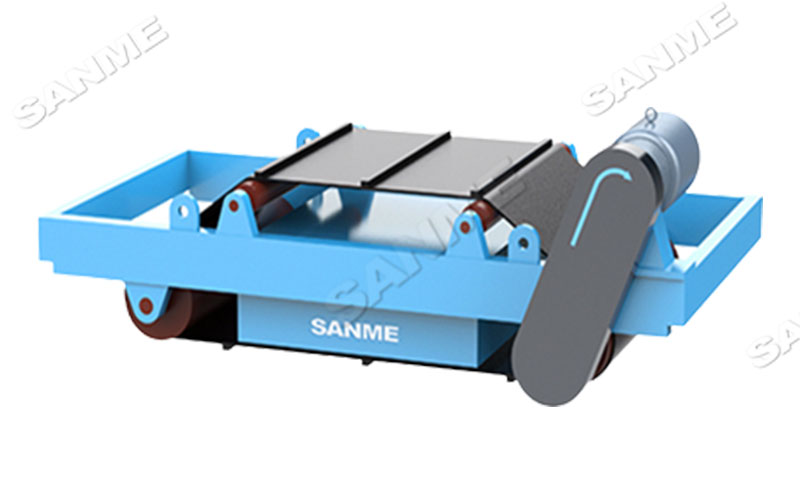

This series of product have a great variety and can be customized for specific requirements.

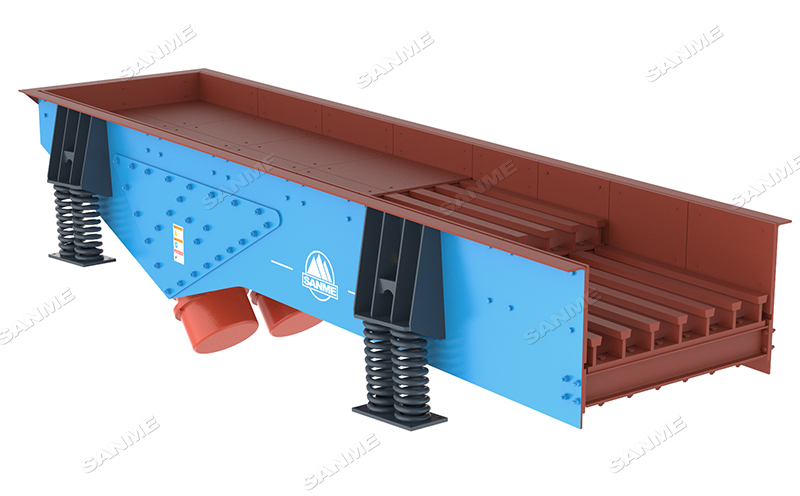

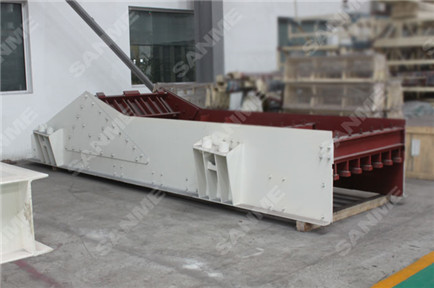

GZT Series Grizzly Vibrating Feeders – SANME

FEATURES AND TECHNOLOGY ADVANTAGES OF GZT SERIES GRIZZLY VIBRATING FEEDER

All types of feeder can control the feeding material quantity automatically or by hand.

Smooth vibration, reliable work and longer service life.

Be able to adjust vibrating force, change and control the flow at any time with convenient and stable adjustment.

Use the vibrating motor to produce vibration force, low noise, low power consumption, excellent adjusting performance and no phenomenon of rushing materials.

Simple structure, reliable operation and convenient adjustment and installation.

Light in weight, small volume and convenient maintenance. Using the body of closed structure can prevent dust contamination.

Product Data

Technical Data of GZT Series Grizzly Vibrating Feeders

| Model | Max Feed Size (mm) | Capacity (t/h) | Motor Power (kw) | Installation Slope (°) | Double Amplitude (mm) | Overall Dimensions(LxWxH) (mm) |

| GZT-0724 | 450 | 30-80 | 2×1.5 | 5 | 4-6 | 700×2400 |

| GZT-0932 | 560 | 80-150 | 2×2.2 | 5 | 4-8 | 900×3200 |

| GZT-1148 | 600 | 150-300 | 2×7.5 | 5 | 4-8 | 1100×4800 |

| GZT-1256 | 800 | 300-500 | 2×12 | 5 | 4-8 | 1200×5600 |

| 400-600 | 2×12 | 10 | 4-8 | |||

| GZT-1256 | 900 | 400-600 | 2×12 | 5 | 4-8 | 1500×6000 |

| 600-800 | 2×12 | 10 | 4-8 | |||

| GZT-1860 | 1000 | 500-800 | 2×14 | 5 | 4-8 | 1800×6000 |

| 1000-1200 | 2×14 | 10 | 4-8 | |||

| GZT-2060 | 1200 | 900-1200 | 2×16 | 5 | 4-8 | 2000×6000 |

| 1200-1500 | 2×16 | 10 | 4-8 | |||

| GZT-2460 | 1400 | 1200-1500 | 2×18 | 5 | 4-8 | 2400×6000 |

| 1500-2500 | 2×18 | 15 | 4-8 | |||

| GZT-3060 | 1600 | 1500-2000 | 2×20 | 5 | 4-8 | 3000×6000 |

| 2500-3500 | 2×20 | 15 | 4-8 |

The equipment capacities listed are based on instantaneous sampling of medium hardness materials.The above data is for reference only,please contact our engineers for equipment selection for specific projects.

APPLICATION RANGE OF GZT SERIES GRIZZLY VIBRATING FEEDER

The vibrating feeders carry the block and grainy materials evenly, regularly and continuously into the targeted device in the process of production. In the sandstone product line, it can not only evenly feed the materials, but screen it as well.

It is widely used in the fields of metallurgical, coal, mineral processing, building materials, chemical engineering, grinding, etc.

WORKING PRINCIPLE OF GZT SERIES GRIZZLY VIBRATING FEEDER

GZT Series Grizzly Vibrating Feeders adopt two vibrating motor with the same capabilities to produce the vibrating force. When both of them make the motion of reverse rotation in the same angular velocity, the inertial force produced by eccentric block is offset and summed up. Thus the great exciting force compels the frame vibrating in the spring support, which drives the materials slide or tossed forward on the frame and achieves the aims of feeding. When the materials cross the grizzly fences, the small-sized materials are fallen through and achieve the effectiveness of sifting.