Due to high reduction ratio, a smaller product size is produced. This puts less pressure on conveyor belt transfer points, which in turn leads to less materials handlings costs, less down-time and less maintenance costs.

SMX Series Gyratory Crusher – SANME

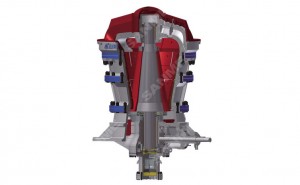

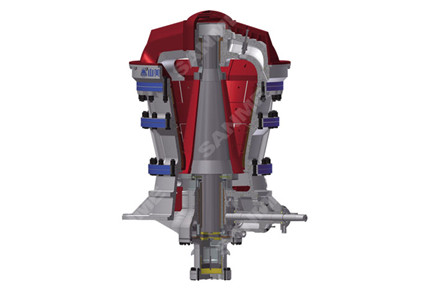

FEATURES AND BENEFITS OF SMX SERIES GYRATORY CRUSHER

Special liner & crushing chamber configuration produces more valuable cubically shaped, lumpy product and less fines.

Special design means crushers do not have to be choke-fed, simplifying plant design & eliminating the need for intermediate stockpile.

The use of spherical bearings instead of a bush arrangement, eliminates point loading in this area – longer bearing life, lower downtime, lower maintenance.

The spherical bearing results in more eccentric movement higher up in the crushing chamber, resulting in the effective nipping and crushing of very large feed sizes.

The spherical bearing allows for smaller gap settings at the discharge, leading to high set under & smaller product sizes.

Heavy duty gyratory design is ideal for crushing hard and abrasive material like iron ore.

Product Data

Heavy duty gyratory design is ideal for crushing hard and abrasive material like iron ore.

| Model | Specification (mm/inch) | Feed Opening (mm) | Motor Power (kw) | O.S.S (mm) / Capacity (t/h) | |||||||

| 150 | 165 | 175 | 190 | 200 | 215 | 230 | 250 | ||||

| SMX810 | 1065×1650 (42×65) | 1065 | 355 | 2330 | 2516 | 2870 | |||||

| SMX830 | 1270×1650(50×65) | 1270 | 400 | 2386 | 2778 | 2936 | |||||

| SMX1040 | 1370×1905(54×75) | 1370 | 450 | 2882 | 2984 | 3146 | 3336 | 3486 | |||

| SMX1050 | 1575×1905(62×75) | 1575 | 450 | 2890 | 3616 | 3814 | 4206 | 4331 | |||

| SMX1150 | 1525×2260(60×89) | 1525 | 630 | 4193 | 4542 | 5081 | 5296 | 5528 | 5806 | ||

| SMX1450 | 1525×2795(60×110) | 1525 | 1100-1200 | 5536 | 6946 | 7336 | 7568 | 8282 | 8892 | ||

The crusher capacities listed are based on instantaneous sampling of medium hardness material. The above data are for reference only, please contact our engineers for equipment selection of specific projects.

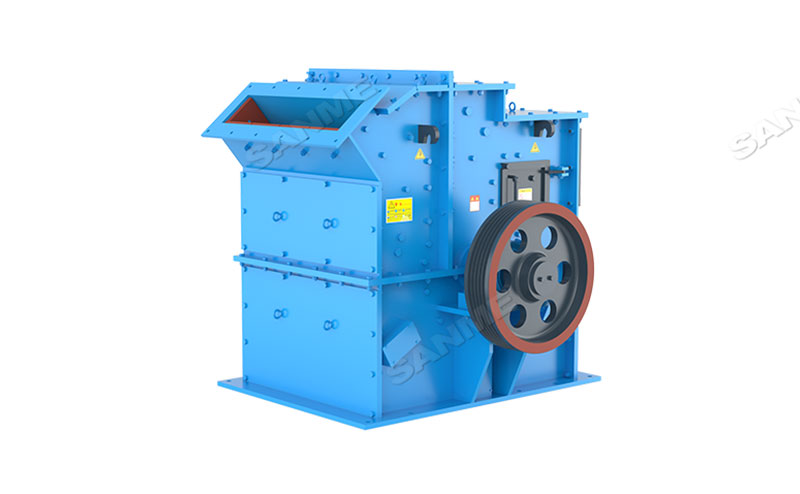

PRODUCT BRIEF INTRODUCTION OF SMX SERIES GYRATORY CRUSHER

SMX Series Gyratory Crusher is a large-scale crushing machine used for primary crushing of various hard ores or rocks, the feed material will be compressed, broken and bended through gyrating movement of breaking head within the chamber. The top of main shaft (assembled with breaking head) is supported within the bushing which is installed in the middle of spider arm; the bottom of the main shaft is mounted in the eccentric hole of bushing. The breaking head gives a gyrating movement around axis line of the machine while bushing rotating, and feed material can be crushed continuously, therefore it is more efficient than jaw crusher.