In traditional wet process of man-made sand, de-soil and dehydrate by spiral sand washer, the loss of man-made sand (especially fine sand) is almost incontrollable. Fine sand recycling equipment reduces the flow away of fine sand effectively, and put it under the control of 5-10%. It well resolves the problem of coarse fineness module of man-made sand, low proportion of stone powder in aggregate processing system.

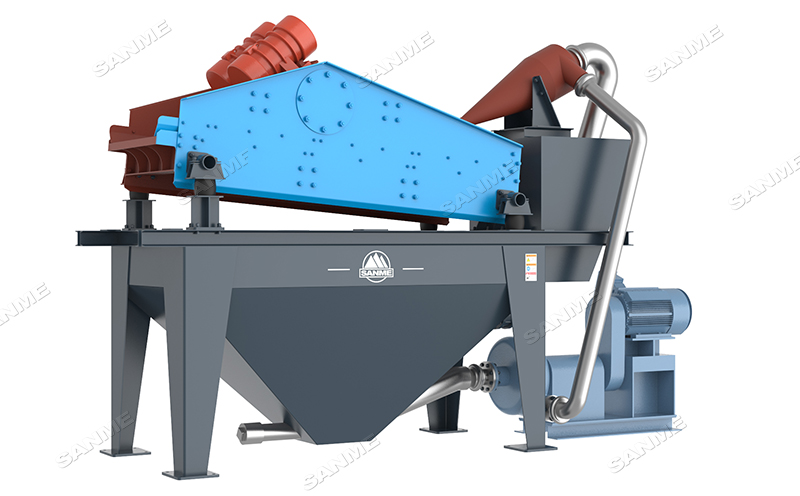

SS Series Fine Sand Collecting System – SANME

TECHNOLOGY ADVANTAGES OF SS SERIES FINE SAND COLLECTING SYSTEM

The spiral (swirler) lined with Polyurethane allows whole system more durable, and accomplishes the functions like condensing pulp, liquid clarification.

Fin sand recycling system recycles in maximum 85% fin particles in total amount of discharge. It possesses unparalleled technical and economic advantages comparing with other equipment.

Vibrating screen is equipped with Polyurethane deck, which is more durable than that of other material, with the meshes uneasy to be blocked.

With particles sufficiently recycled, the workload and cleaning cost in sedimentation basin would be reduced.

Fine sand recycling system reduces the time of random piling of fin material, and realizes direct transportation and market supplying.

Different design for different customer requirement.

Product Data

Technical Data of SS Series Fine Sand Collecting System

| Model | Pump | Cyclone Spec. (mm) | Dewatering Screen | Capacity (t/h) | Overall Dimensions (LxWxH) (mm) | |||

| Power (kw) | Size (inch) | Model | Deck Size (m2) | Power (kw) | ||||

| SS-06-300 | 7.5 | 2″ | 300 | 0.6×1.5 | 0.9 | 2×0.75 | 40-60 | 3590x1342x2561 |

| SS-08-300 | 18.5 | 3″ | 300 | 0.8×2.25 | 1.8 | 2×1.5 | 40-100 | 4565x1402x2947 |

| SS-10-350 | 18.5 | 4″ | 350 | 1.0×2.25 | 2.25 | 2×1.5 | 70-114 | 4622x1682x4237 |

| SS-12-550 | 37 | 5″ | 550 | 1.2×3.0 | 3.6 | 2×2.2 | 150-300 | 6009x2014x3820 |

| SS-12-650 | 37 | 5″ | 650 | 1.2×3.0 | 3.6 | 2×2.2 | 150-320 | 6011x2028x4060 |

| SS-14-750 | 45 | 6″ | 750 | 1.4×3.0 | 4.2 | 2×3.0 | 180-343 | 6013x2042x4300 |

| SS-14-750II | 55 | 6″ | 750 | 1.4×3.0 | 4.2 | 2×3.0 | 230-420 | 6659x2042x4202 |

| SS-16-2×650 | 55 | 10″ | 2×650 | 1.6×3.75 | 6 | 2×5.5 | 350-800 | 7384x2350x4650 |

| SS-18-2×750 | 75 | 10″ | 2×750 | 1.8×3.75 | 6.75 | 2×7.5 | 350-1000 | 7780x2545x4800 |

The equipment capacities listed are based on instantaneous sampling of medium hardness materials.The above data is for reference only,please contact our engineers for equipment selection for specific projects.

PRODUCT INTRODUCTION OF SS SERIES FINE SAND COLLECTING SYSTEM

Presently, the most man-made sand production line adopts wet process. No matter which model sand washer they put in use, the biggest weakness is serious loss of fine sand ( below 0.16mm), sometimes the loss is up to 20%. The problem is not only the sand loss itself, but also results in unreasonable sand gradation and more coarse fineness module, it influences the sand quality. Moreover, excessive sand flow away leads to environmental pollution. In response to this problem, our company elaborates SS series fine sand recycling system. This system absorbs world’s advanced technology, and takes the view of practical working situation. It is ranged in top class international. The applicable fields are aggregate processing system for building hydro power, processing system for glass raw material, man-made sand producing line, coarse coal slime recycling and environmental protection system (mud purification) in coal preparation plant, etc. It can works effectively in collecting fine sand.

WORKING PRINCIPLE OF SS SERIES FINE SAND COLLECTING SYSTEM

Structure: It is mainly composed of motor, residue slurry pump, cyclone, vibrating screen, rinse tank and recycling box, etc.

Working principle: The compound of sand and water is transported to the cyclone by pump, and the fine sand after centrifugal classification concentration is provided to the vibrating screen by the grit setting mouth, after vibrating screen dewater, the fine sand and water are effectively separated. Through the recycling box, little fine sand and mud return again to the rinse tank, and then they are exhausted from the discharge hole when the rinse tank liquid level is too high. The material weight concentration recovered by the linear vibrating screen is 70%-85%. Adjusting the fineness module can be realized by changing the pump rotating speed and pulp concentration, regulating the overflow water yield and replacing the grit mouth, thus achieves its three functions—washing, dewater and classification.