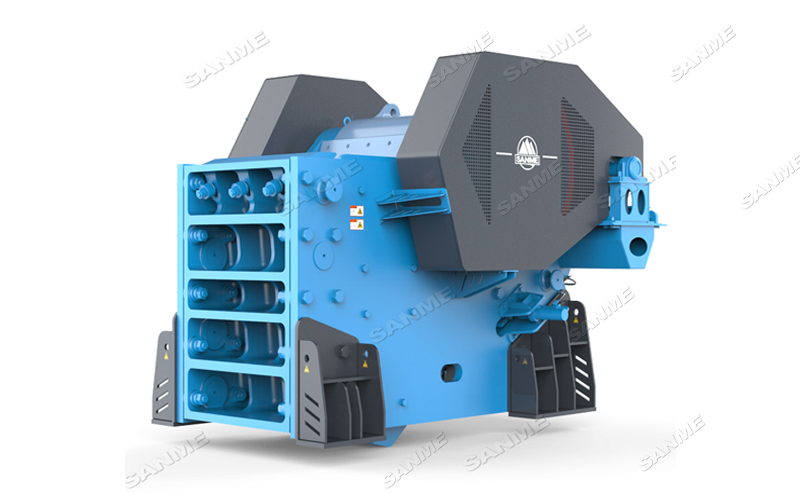

High-performance VSI series Vertical Impact Crusher

PP Portable Sand Maker – SANME

TECHNOLOGY ADVANTAGES OF PP PORTABLE SAND MAKER

Vehicle-mounted feeder, vibrating screen, belt conveyor.

Traction steering shaft, convenient for highway transportation.

Vehicle mounting support, fast and convenient for installation in the site.

Integration of the mating motor and control box.

Product Data

Technical Data of PP Portable Sand Maker

| Model | PP5000VSI | PP5000VSIS | PP6000VSI | PP6000VSIS | PP7000VSI | PP7000VSIS |

| Transport dimensions | ||||||

| Length(mm) | 9800 | 11280 | 11500 | 15470 | 14000 | 15420 |

| Width(mm) | 2490 | 2780 | 2780 | 2780 | 3300 | 2780 |

| Height(mm) | 4200 | 4100 | 3850 | 4180 | 4160 | 4250 |

| Weight(kg) | 21600 | 28000 | 22100 | 32600 | 23200 | 33200 |

| Axle weight(kg) | 14600 | 19200 | 15100 | 22300 | 15100 | 21700 |

| King pin weight(kg) | 7000 | 8800 | 7000 | 10300 | 8100 | 11500 |

| VSI Sand Maker | ||||||

| Model | VSI-5000 | VSI-5000 | VSI-6000 | VSI-6000 | VSI-7000 | VSI-7000 |

| Feed opening(mm) | 65(80) | 65(80) | 70(100) | 70(100) | 70(100) | 70(100) |

| Throughput capacity range(t/h) | 80-150 | 80-150 | 120-250 | 120-250 | 180-350 | 180-350 |

| Screen | ||||||

| Model | 3YK1548 | 3YK1860 | 3YK2160 | |||

| BELT CONVEYOR | ||||||

| Model | B650*6.5 | B800*7.2 | B800*6.7 | B1000*8.6 | B1000x7.2 | B1000x7.2 |

| Number of Axles | 1 | 2 | 2 | 2 | 3 | 2 |

The crusher capacities listed are based on instantaneous sampling of medium hardness material. The above data are for reference only, please contact our engineers for equipment selection of specific projects.

THE OUTSTANDING PERFORMANCE OF PP PORTABLE SAND MAKER

Great Mobility

PP Portable Sand Maker are of short length. Different crushing equipment is separately installed on a separate mobile chassis. Its short wheelbase and tight turning radius mean they can be transported on highway and moved at crushing sites.

Lower Transportation Cost

PP Portable Sand Maker can crush materials on-site. It is unnecessary to carry the materials from one site and then crush them in another one, which can greatly lower the transporting cost for off-site crushing.

Flexible Configuration and Great Adaptability

According to the different requirements of different crushing process, Portable Sand Maker can form the following two processes of “crushing first, screening second” or “screening first, crushing second”. The crushing plant can be composed of two-stage plants or three-stage plants. The two-stage plants consists primary crushing plant and secondary crushing plant, while the three-stage plants includes primary crushing plant, secondary crushing plant and tertiary crushing plant, each of which is of high flexibility and can be used individually.

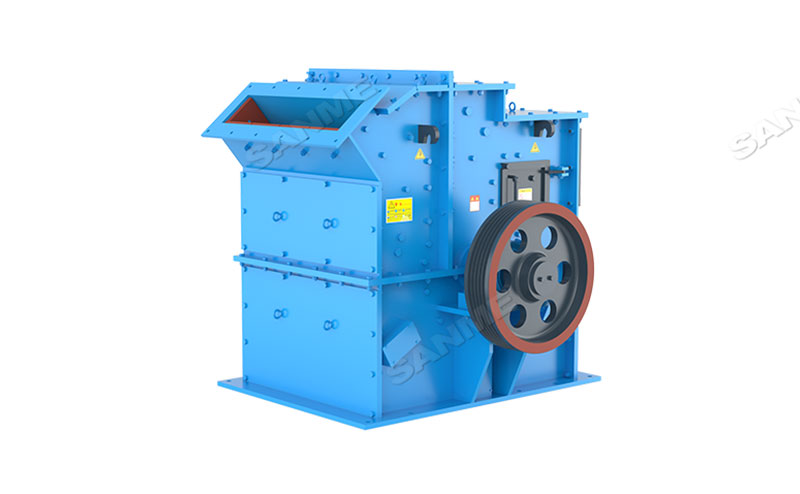

THE DESIGN FEATURES OF PP PORTABLE SAND MAKER

Mobile chassis conforms to the international standards. It has standard lighting and braking system. The chassis is heavy-duty design with big section steel.

The girder of mobile chassis is designed to be U style so that the overall height of the mobile crushing plant is reduced. So the loading cost is reduced greatly.

Adopt hydraulic leg(optional) for lift installation. Hopper adopt unitized design, reduce the transport height greatly.

Working principle of PP Portable Sand Maker

Material preselected by the feeder, and the VSI sand maker makes the sand production. A closed-circuit system is formed through the vibrating screen, which realizes materials cycle broken and can reduces processing sectors effectively. The final material is discharged by belt conveyor to make continuous crushing operations.