Check the vortex chamber to see if the door is closed tightly before driving to prevent sand and stone from rushing out of the vortex chamber observation door and causing danger.

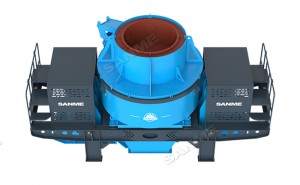

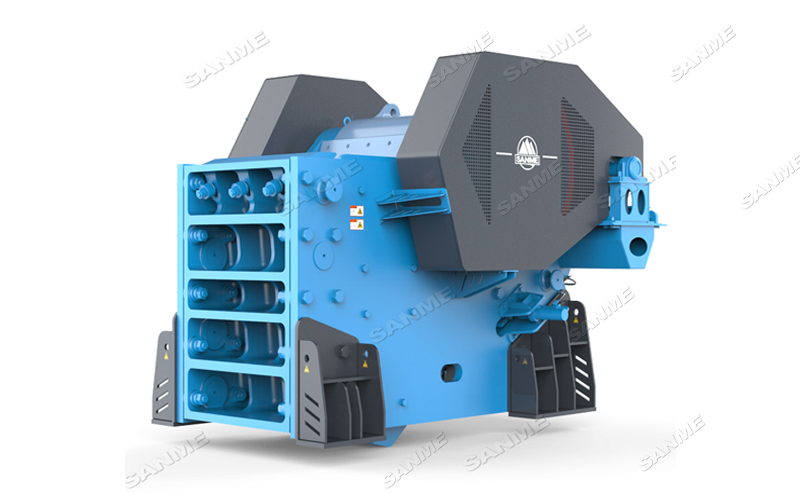

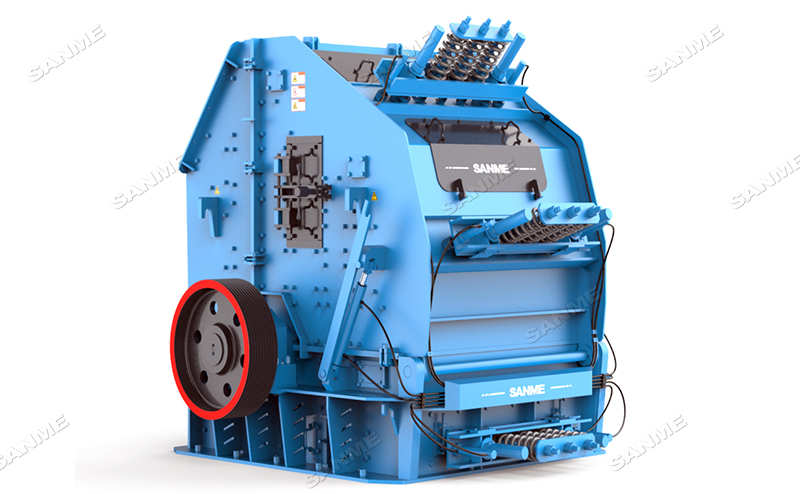

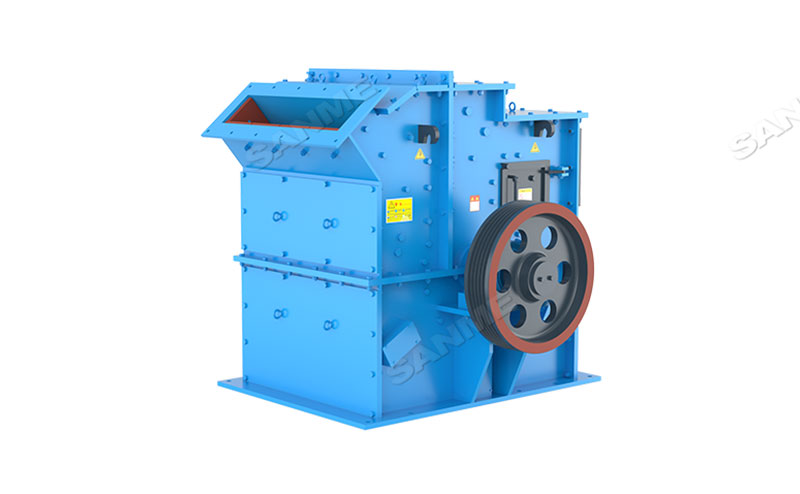

VC7 Series Vertical Shaft Impact Crusher – SANME

Operation specification of sand making machine

Check the rotation direction of the impeller, from the direction of the inlet, the impeller should be rotated counterclockwise, otherwise the motor wiring should be adjusted.

The starting sequence of sand making machine and conveying equipment is: discharge → sand making machine → feed.

The sand making machine must be started without load and can be fed after normal operation. The stop order is the opposite of the start order.

The feeding particles in strict accordance with the requirements of the provisions, prohibit more than the specified material into the sand making machine, otherwise, it will cause the impeller imbalance and excessive wear of the impeller, the base to cause blockage of the impeller channel and the central feeding pipe, so that the sand making machine can not work normally, found that the bulk of the material should be eliminated in time.

The lubrication of the machine: use the required special grade of automotive grease, add the amount of 1/2-2/3 of the bearing cavity, and add the appropriate amount of grease for each working shift of the sand making machine.

Patented feed adjustment device provides an accurate control of ratio between central feeding and the cascade. Hydracascade feed technology not only improved energy availability and increased throughput, but also managed product shape and fines content via cascade feed.

The tension force of the transmission triangle tape should be adjusted appropriately to ensure that the force of the triangle tape is uniform. When the double motor is driven, the triangle tape on both sides should be grouped and selected, so that each group length is as consistent as possible. Should be adjusted so that the current difference between the two motors does not exceed 15A.

Product Data

Technical Data of VC7(H) Series Vertical Shaft Impact Crusher:

| Model | Rotation Speed of Impeller (r/min) | Max Feed Size (mm) | Throughput (t/h) (Full feeding center / center plus waterfall feeding) | Motor Power (kw) | Overall Dimensions (mm) | |

| VC726L | 1881-2499 | 35 | 60-102 | 90-176 | 110 | 3155x1941x2436 |

| VC726M | 70-126 | 108-211 | 132 | |||

| VC726H | 96-150 | 124-255 | 160 | |||

| VC730L | 1630-2166 | 40 | 109-153 | 145-260 | 180 | 4400x2189x2501 |

| VC730M | 135-200 | 175-340 | 220 | |||

| VC730H | 160-243 | 211-410 | 264 | |||

| VC733L | 1455-1934 | 55 | 165-248 | 215-415 | 264 | 4800x2360x2891 |

| VC733M | 192-286 | 285-532 | 320 | |||

| VC733H | 238-350 | 325-585 | 2*200 | |||

| VC743L | 1132-1504 | 60 | 230-346 | 309-577 | 2*200 | 5850x2740x3031 |

| VC743M | 246-373 | 335-630 | 2*220 | |||

| VC743H | 281-405 | 366-683 | 2*250 | |||

| VC766 | 1132-1414 | 60 | 330-493 | 437-813 | 2*280 | 6136x2840x3467 |

| VC766L | 362-545 | 486-909 | 2*315 | |||

| VC766M | 397-602 | 540-1016 | 2*355 | |||

| VC788L | 970-1120 | 65 | 460-692 | 618-1154 | 2*400 | 6506x3140x3737 |

| VC788M | 560-848 | 761-1432 | 2*500 | |||

| VC799L | 780-920 | 65 | 644-967 | 865-1615 | 2*560 | 6800x3340x3937 |

| VC799M | 704-1068 | 960-1804 | 2*630 | |||

Technical Data of VCU7(H) Series Vertical Shaft Impact Crusher:

| Model | Rotation Speed of Impeller (r/min) | Max Feed Size (mm) | Throughput (t/h) (Full feeding center / center plus waterfall feeding) | Motor Power (kw) | Overall Dimensions (mm) | |

| VCU726L | 1881-2499 | 55 | 86-143 | 108-211 | 110 | 3155x1941x2436 |

| VCU726M | 98-176 | 124-253 | 132 | |||

| VCU726H | 132-210 | 143-300 | 160 | |||

| VCU730L | 1630-2166 | 65 | 150-212 | 162-310 | 2×90 | 4400x2189x2501 |

| VCU730M | 186-280 | 203-408 | 2×110 | |||

| VCU730H | 220-340 | 245-480 | 2×132 | |||

| VCU733L | 1455-1934 | 80 | 230-338 | 255-497 | 2×132 | 4800x2360x2891 |

| VCU733M | 268-398 | 296-562 | 2×180 | |||

| VCU733H | 327-485 | 373-696 | 2×200 | |||

| VCU743L | 1132-1504 | 100 | 305-467 | 362-678 | 2×200 | 5850x2740x3031 |

| VCU743M | 335-506 | 379-746 | 2×220 | |||

| VCU743H | 375-540 | 439-800 | 2×250 | |||

| VCU766L | 1060-1240 | 100 | 400-600 | 490-850 | 2×280 | 6136x2840x3467 |

| VCU766M | 450-650 | 530-960 | 2×315 | |||

| VCU766H | 500-700 | 620-1040 | 2×315 | |||

| VCU788L | 764-918 | 150 | 800-1000 | 800-1200 | 2×450 | 6506x3140x3737 |

| VCU788M | 900-1200 | 900-1400 | 2×500 | |||

The crusher capacities listed are based on instantaneous sampling of medium hardness material. The above data are for reference only, please contact our engineers for equipment selection of specific projects.

Note: 1. VC7H series is an electric hydraulic pump station, and VC7 series is a manual hydraulic pump station;

2. VCU7 (H) is an open impeller for low abrasive materials; VC7 (H) is a round impeller for high abrasive materials.